It consists of conveyor modules that allow you to build a sorter of any size with precisely defined functionality. The modular design allows for quick and cheap modification and reconfiguration, i.e. replacement of any element and expansion of the system. A high-performance 24V switch is used to change the direction of the flow of items, the additional advantage of which is the low level of emitted noise. After changing the direction, the load can continue moving at an angle of 30°, 45° or 90° to the main line. Drop slots are available in several variants, e.g. as end stations using gravity conveyors or zone conveyors buffering packages. The system does not require a pneumatic installation. The change in the direction of the rollers in the switch is controlled electrically.

.webp)

Product specifications:

Transported products: Cartons Boxes Trays

Ambient temperature: 0°C ÷ 40°C

Speed: max. 1 m/s

Voltage type: 24V

Conveyor width: 420, 620, 820 mm

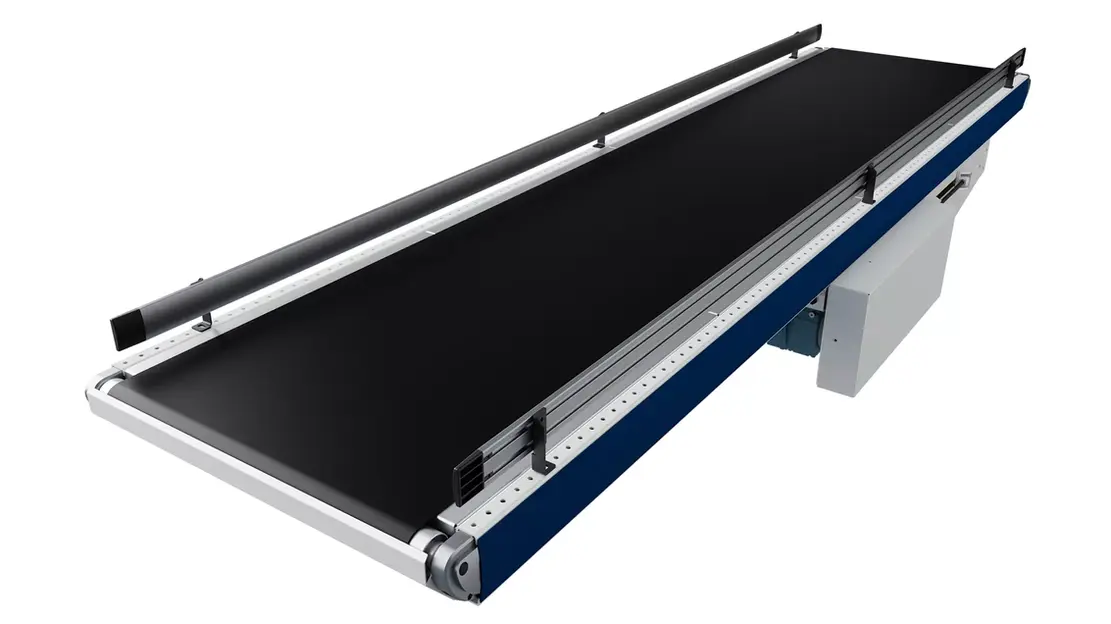

Transmission element: Multi-ribbed belt PU belt

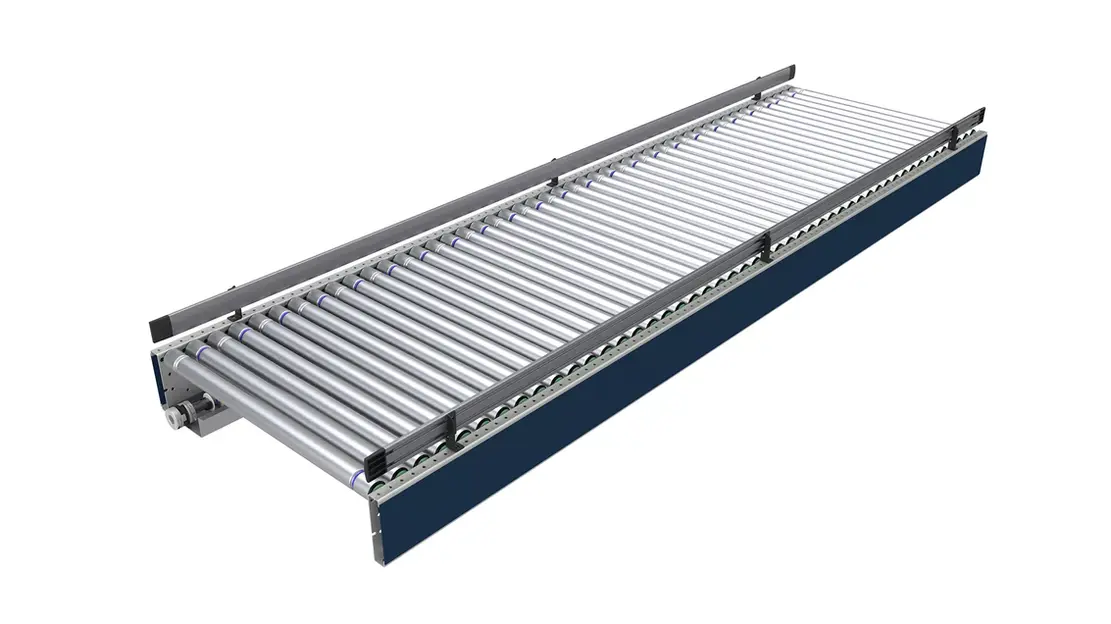

Drive: 24V electric rollers

Number of roller rows: 2 ÷ 6

Minimum product dimensions: 200 x 100 x 20 mm

Maximum product dimensions: 1200 x 800 x 600 mm

Product weight: 0.25 - 32 kg

Actual capacity: up to 2700 packages/h

Additional elements:

Band, Band Ends, Supports, Connectors, Control Cabinets.